Top Floor Grinding Machine with Vacuum - Leading China Manufacturer

When I think about floor maintenance, efficiency and quality are top priorities. That's why I always choose our Floor Grinding Machine With Vacuum, designed specifically for the rigorous demands of industrial use. Manufactured in China, I’ve seen firsthand how precision engineering guarantees durability and performance. This machine not only grinds concrete and stone surfaces but also features a powerful vacuum system that captures dust while you work, ensuring a cleaner environment and enhancing air quality. With its user-friendly design, I find it easy to operate and perfect for various projects, whether large or small. I highly recommend this product to any B2B purchaser looking for reliable equipment that stands the test of time. Teaming up with a trusted manufacturer means you’re investing in advanced technology and exceptional support. Don't let dust and debris slow you down; elevate your floor grinding experience and achieve professional results effortlessly.

Floor Grinding Machine With Vacuum Your Trusted OEM Partner Service Backed by Expertise

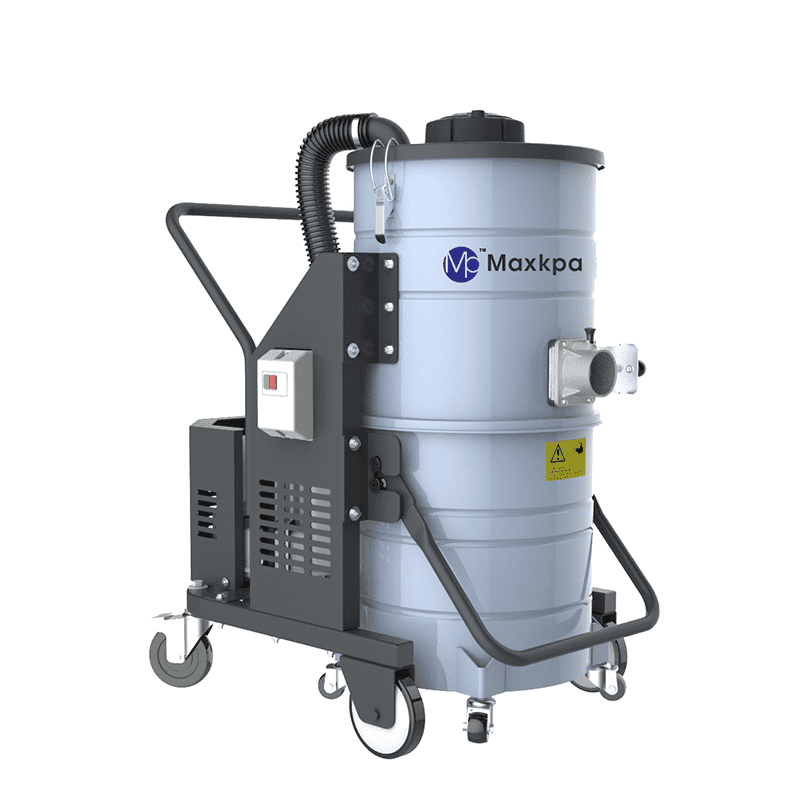

When it comes to surface preparation and finishing, the efficiency of floor grinding machines is paramount. A vacuum-integrated grinding solution not only ensures a cleaner workspace but also enhances the grinding process by minimizing dust and debris. This powerful combination is essential for maintaining a safe and productive environment, especially in large-scale commercial projects. By partnering with an experienced OEM service provider, you can access cutting-edge technology that elevates your operations and enhances your project outcomes. The expertise offered by a trusted OEM partner is invaluable. With a strong focus on innovation and quality assurance, these manufacturers deliver tailored solutions that meet diverse market needs. From robust designs to state-of-the-art vacuum systems, every aspect of the machine is engineered for optimal performance. By leveraging advanced materials and manufacturing techniques, they ensure longevity and reliability, so you can maximize your investment with machines that stand up to rigorous demands. Choosing the right OEM partner is crucial for global buyers looking to optimize their procurement strategies. With a commitment to quality, efficiency, and customer satisfaction, the right partner will not only provide superior products but also offer ongoing support and service. This collaborative approach promotes a seamless integration of equipment into your operations, paving the way for successful outcomes in your flooring projects. Ultimately, investing in advanced floor grinding machines with vacuum systems can significantly enhance your operational capabilities and drive business growth.

Floor Grinding Machine With Vacuum Your Trusted OEM Partner Service Backed by Expertise

| Model | Power (kW) | Voltage (V) | Weight (kg) | Grinding Diameter (mm) | Vacuum Type | Operating Speed (rpm) |

|---|---|---|---|---|---|---|

| FGM-300 | 4.0 | 220 | 100 | 300 | Cyclonic | 150 |

| FGM-400 | 5.5 | 380 | 120 | 400 | Bag | 120 |

| FGM-500 | 7.5 | 220/380 | 140 | 500 | HEPA | 100 |

| FGM-600 | 11.0 | 380 | 160 | 600 | Cyclonic | 80 |

Related Products