Top China Manufacturer of Thinset Grinders with Vacuum Features

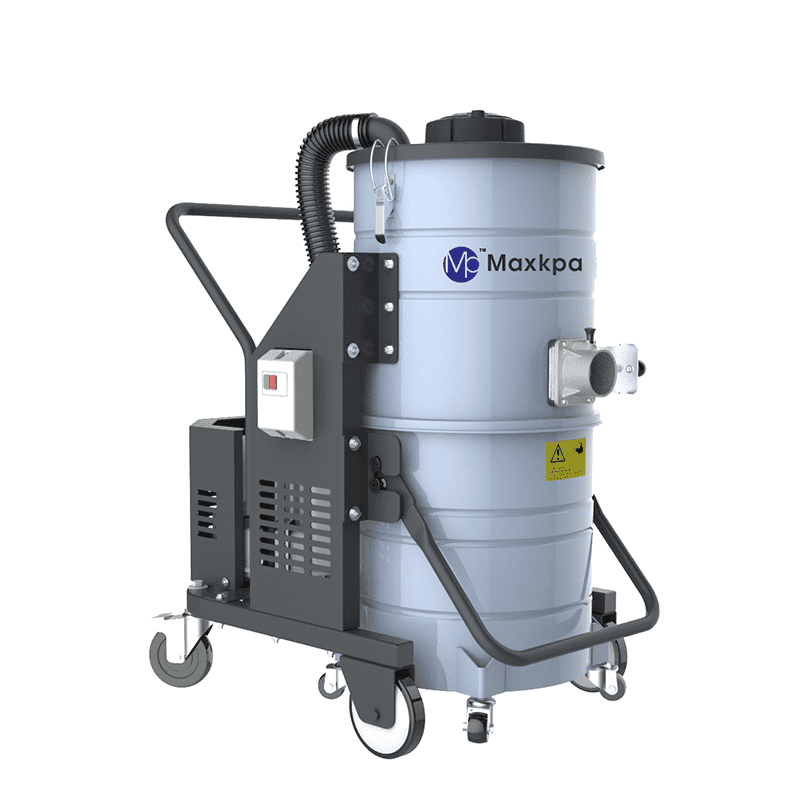

For those in the construction and renovation industry, my Thinset Grinder With Vacuum is an essential tool that revolutionizes your workflow. Designed to efficiently grind and remove thinset, it ensures a dust-free environment, making job sites safer and cleaner. I take pride in sourcing this equipment directly from reliable manufacturers in China, guaranteeing high quality and durability that you can trust. What sets my grinder apart is its powerful suction system, which minimizes mess and enhances productivity. I’ve personally tested this machine in various projects, and it consistently delivers impressive results. Its user-friendly design and portability mean you can easily transport it between job sites without hassle. Plus, with competitive pricing and bulk order options, this grinder is perfect for both small contractors and larger organizations. If you're looking for a dependable solution to streamline your work, my Thinset Grinder With Vacuum is the ideal choice for your next project. Let’s connect and discuss how we can meet your needs.

Thinset Grinder With Vacuum For the Current Year More Than a Supplier - A Partner

In the competitive landscape of construction and renovation, partnering with the right supplier can significantly enhance your project outcomes. The "Thinset Grinder With Vacuum" has evolved beyond just being a tool; it represents a collaborative approach to achieving superior results in tile setting and surface preparation. This innovative equipment is designed to not only streamline the grinding process but also to minimize dust and enhance workplace safety, ensuring a cleaner and healthier environment for your team. What sets the Thinset Grinder apart is its ability to serve as a reliable partner in your projects, offering you more than just a supply of equipment. It combines efficiency with advanced technology, allowing contractors and DIY enthusiasts alike to achieve precise finishes while saving time and resources. By integrating a vacuum system, the grinder addresses the common issues of dust pollution, promoting a more sustainable working environment and adhering to stricter health regulations. Investing in a Thinset Grinder with a vacuum system is not merely about purchasing a product; it’s about joining forces with a partner who understands the challenges of the industry and supports your goals. This relationship is key to driving forward innovation and efficiency in your projects, ensuring that every tile laid is perfect and every space transformed reflects the quality you stand for. Embrace the future of construction tools, and let your projects flourish with the right partnership.

Thinset Grinder With Vacuum For the Current Year More Than a Supplier - A Partner

| Feature | Description | Benefits | Applications | Maintenance |

|---|---|---|---|---|

| Dust Extraction | Integrated vacuum system for cleaner workspace. | Reduces airborne dust particles, improves health and safety. | Floor installation, wall tiling, and stone polishing. | Regular filter cleaning and vacuum checks. |

| Power Efficiency | High-torque motor for effective grinding. | Saves time and energy on large projects. | Tile leveling systems and adhesive removal. | Check motor brushes periodically. |

| Versatility | Compatible with various grinding pads. | Enables handling of diverse materials and surfaces. | Ceramic, porcelain, and natural stone. | Use recommended pads for each material type. |

| User-Friendly Design | Ergonomic handles and easy controls. | Minimizes user fatigue and improves control. | DIY projects, professional installations. | Regularly inspect handles and control functions. |

Related Products